SACURA-PRO production standards

The production of protective and translucent structures is a complex process that requires a responsible approach to the implementation of each stage. Everything from the choice of materials and design to the direct manufacture and testing of finished products is important. Even a minor mistake can lead to serious adverse consequences:

- decrease in strength and other operational properties;

- deformations of individual components;

- size changes, which in the future will cause difficulties during installation and use of structures;

- an increase in the number of shortages and an increase in the company’s current costs;

- loss of trust of customers who receive goods of inadequate quality.

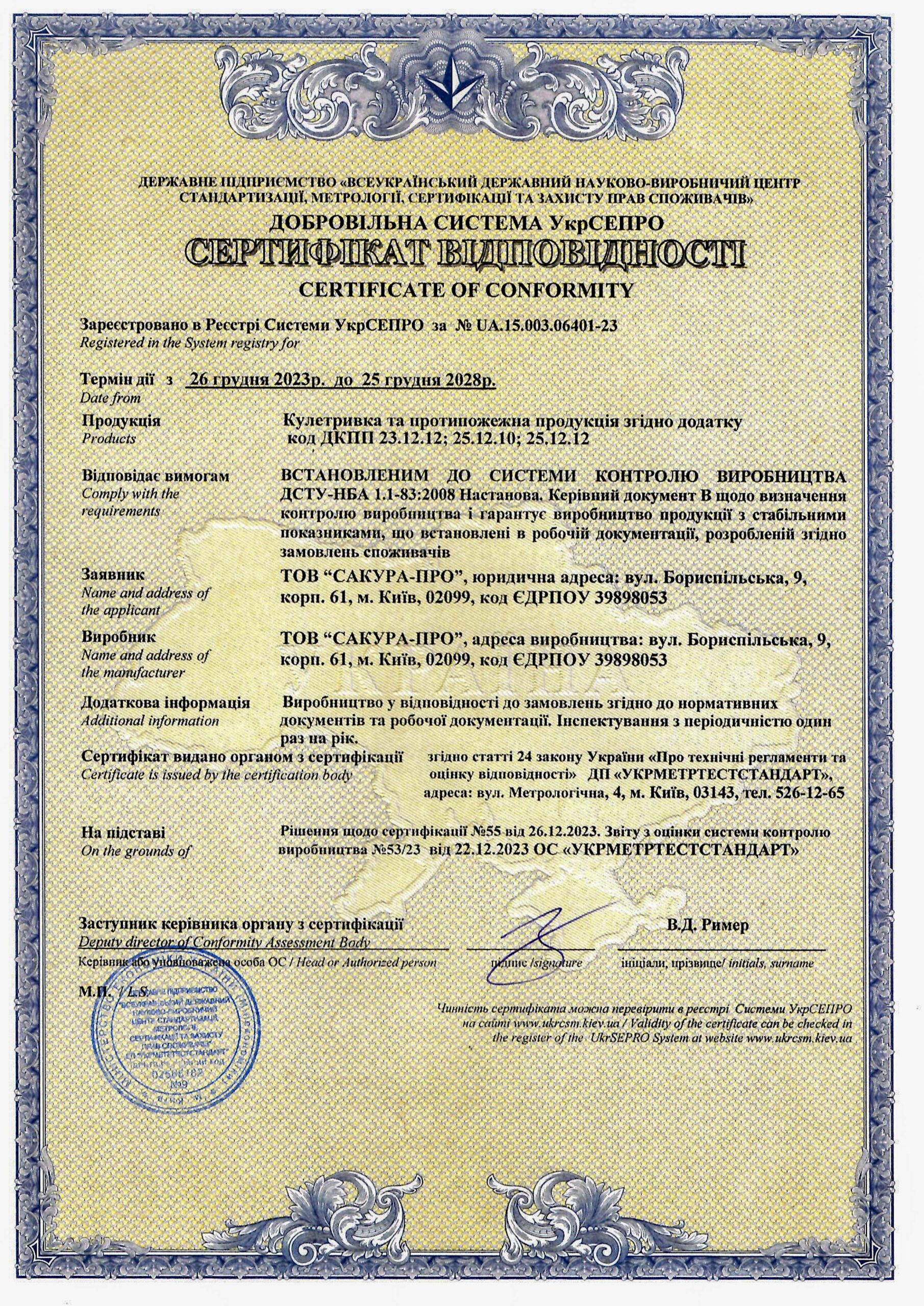

To avoid the listed troubles, it is necessary to carefully control the technological process, involve professional workers, ensure maximum automation and integrate quality standards. The last point is especially important. The SACURA-PRO company has been working successfully on the Ukrainian market for a long time and organizes its activities in such a way as to fulfill international requirements and justify the trust of customers. We are constantly improving and offer customers reliable and durable designs with high protective properties. Next, we will tell you what standards are used in production and what results it gives.

What are quality standards and why should they be used?

In Ukraine and other countries, there are thousands of enterprises specializing in the creation of protective glass and structures, as well as facade glazing systems. The international standard is an effective tool for their differentiation depending on the quality of the offered products. This is a set of requirements for product parameters, features of their operation, transportation, storage, sale and disposal. EN standards adopted by CEN are used in Europe.

Standardization of production is equally important for the enterprise, consumers and the state, as it allows:

- Unify products manufactured in different countries.

- Simplify and speed up for buyers the choice of a verified seller who will be able to provide protective structures with the required characteristics.

- Stimulate the integration of advanced technological solutions.

- Reduce the number of unscrupulous manufacturers.

- Reduce the negative impact on the environment.

- Provide favorable conditions for international trade.

- To optimize the production process, providing the enterprise with a basis for a quick and effective solution of technological tasks.

- Create a relationship of trust between the producer and the end consumer.

- Reduce the probability of low-quality products entering the market, as well as the appearance of negative consequences from their use.

In fact, if the company adheres to the basic standards for its industry, then the customer can trust it and order products. It is also very important that the manufacturer can provide documentary evidence of compliance with international requirements for the characteristics of protective glass systems.

It should be noted that compliance with European standards is not mandatory for manufacturers of translucent structures and protective glass if they intend to sell the product within their home country. Therefore, the willingness to do this and the efforts made testify to the company’s desire to provide customers with high-quality products of an international level and to be ahead of competitors.

What standards does SACURA-PRO follow?

Having started work in 1991, our company witnessed the development of many Ukrainian standards and was one of the first to integrate them into its activities. International standards were also gradually introduced:

- EN 1063 and EN1522 are standards that regulate the bullet resistance of protective glass structures. We create structures from multilayer bullet-resistant glass that meets the requirements of classes BR4NS, BR6NS, BR7NS, as well as structures according to class FB 4, FB 6 and FB 7.

- Stanag 4569 is a NATO standard that determines the strength of armored glass.

- ASTM is a set of standards that regulate the properties of materials, types and processing and manufacturing methods, as well as other requirements for rolled metal.

- ISO 12543 – Laminated glass and safety laminated glass.

- A set of standards for fire protection structures and others.

The SACURA-PRO company is focused on achieving maximum protection, therefore it is a reliable partner for private and corporate clients who wish to receive quality products of Ukrainian production.

Features of protective and translucent structures made in accordance with European standards

Our products are adapted to modern Ukrainian realities and fully meet customer requests:

- withstands significant ballistic loads (bullets from pistols and rifles);

- has high heat and sound insulation properties;

- has a moderate weight;

- has the required degree of transparency;

- preserves the initial parameters for many years;

- resistant to temperature changes.

We can guarantee the quality and reliability of every product we create, and these properties are confirmed not only by grateful customer reviews, but also by a long period.